Tailoring hundreds of costumes, prepping sensitive lab experiments, mounting library exhibits — the work of a university demands a sweeping range of skills, expertise, and equipment. From sewing machines to medical manikins, these are some of the tools staff use to support Yale’s mission. What’s yours?

Juki Sewing Machine

Mary Zihal, senior draper

David Geffen School of Drama at Yale/Yale Repertory Theatre

The costume shop is abuzz. Its walls are crowded with colorful fabric, thread spools, design sketches, and never-ending notions, a stimulating backdrop for the whir of sewing machines as Mary Zihal and colleagues work on all stages of constructing theatrical garments.

Here, Mary is sewing a late-1950’s-style blouse in a floral silk fabric for the character of Martha in the Edward Albee drama, “Who’s Afraid of Virginia Woolf?” It’s one of 15 costume pieces she and her colleagues produced for the play. For each Yale Repertory Theatre and student production, a total of eight per year, Mary and her colleagues typically create six to eight costumes from scratch. They also alter and augment up to 150 existing costumes a year, informed by the show designer’s vision and the drapers’ historical research.

Mary’s work is rooted in the personal; her mother was a garment worker in New York City who was proud of how many nightgowns she could make in a day. After Mary earned her MFA in costume design, she began working in theatrical costume shops and gravitated toward the construction end of costume production. With pride, she says she finds it “poetic” that she has followed in her mother’s footsteps.

Photo by Robert DeSanto

Photo by Robert DeSanto

Medical Manikin

Gustavo Carrillo, simulation lab technologist

School of Nursing

The figure on the bed moans as blood seeps from her head wound. She starts to breathe erratically and her pulse skyrockets, setting off an alarm on the vital stats monitor. This may look like a scene out of a TV medical drama, but this patient at the School of Nursing’s Simulation Lab is one of 16 high-tech manikins, hyper-realistic simulators used for training nurses for a variety of scenarios.

Gustavo Carrillo brings these medical manikins to life using a moulage kit (make-up colors and palettes, brushes, adhesives, cleaning supplies, food colorants, silicone mixtures, gloves, scissors, tweezers) to create fake blood, wounds, and bodily fluids. He operates the manikin from a control room, opening and closing her eyes, making her breathe, adjusting her vitals, and sometimes serving as her voice.

At 18, Gustavo immigrated from Guatemala to the U.S. and earned his degree in computer science with a minor in business administration from Albertus Magnus College. “I think I was always meant to be here, to provide my expertise for the good of the students,” he says. “It is a responsibility I carry with me every day, to demonstrate that as part of the Latino community, we came to this country to work hard for a better future for our families.”

Photo by Robert DeSanto

Photo by Robert DeSanto

PH Meter and Autoclave Machine

Aiwei Sui, lab technician

Research Support Services, West Campus

In the chemical room of the lab of Associate Professor of Molecular Biophysics and Biochemistry Nikhil Malvankar, Aiwei Sui mixes solutions for experiments, prepares assorted culture mediums, and measures their acidity and alkalinity with a PH Meter (pictured above).

In her role as lab technician, Aiwei supports 14 labs at Yale West Campus, including Mavlankar’s in the Advanced Biosciences Center. The researchers she supports work on a variety of projects, such as exploring how genetic traits and environmental factors contribute to cancer, and how bacteria breathe in environments without oxygen.

In the center’s basement, Aiwei uses an autoclave the size of a dishwasher to sterilize flasks, cylinders, and other scientific glassware, enabling researchers to perform contamination-free experiments. She seals the glassware in the autoclave, which bathes the equipment in high-pressure steam, heated to 250 degrees Fahrenheit, for 15 to 20 minutes. “Although the tools I use are basic,” she says, “they are an integral part of important scientific work.”

Photo by Robert DeSanto

Photo by Robert DeSanto

M Mount

Kerri Sancomb, exhibition production manager

Yale Library Center for Preservation and Conservation

Kerri Sancomb comes from a “family of makers.” Her mother, a teacher, often sewed while Kerri was growing up, and her dad is a skilled woodworker who taught Kerri how to use the tools in his workshop. That some of the skills they passed on now serve her work building exhibits in Yale’s libraries “makes perfect sense,” she says.

Among the many tools that Kerri and her team rely on to provide access to university treasures while preserving them is the M Mount, an eponymously shaped plexiglass support used to hold bound materials securely and unobtrusively. To accommodate the height and width of open books, including those of an irregular size or shape, Kerri modified the M Mount by separating it into halves, which are secured in place with a piece of matboard (pictured above, holding a book).

Library staff, faculty, and student curators bring their ideas to Kerri’s team. Together, they select the materials for exhibitions like “Matters of Color/Color Matters,” an exploration of how color is used across disciplines and applications, both technically and symbolically, on view at Sterling Memorial Library’s Exhibition Corridor through April 23, 2023. Says Kerri, “I love the act of making things in the service of others.”

Photo by Robert DeSanto

Photo by Robert DeSanto

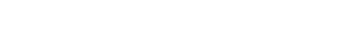

Battery-operated Landscape Equipment

Lou Sommo, lead mechanic

Landscape and Grounds Maintenance

Every day at 6:00 a.m., Lou Sommo, lead mechanic for landscape and grounds maintenance, begins inspecting the fast-growing fleet of battery-powered landscape equipment that his colleagues use to mow, weed, and hedge, and to clear debris. Lou repairs and maintains the equipment — addressing cracks in the frames, leaky hoses, and dirty parts — using tools like wrenches, soldering wires and irons, volt meters, and hand-held diagnostic computers.

His department has nearly completed its conversion to all-electric machines for the central campus, a transition that began in 2013 and was codified four years later as part of the Yale Sustainability Plan 2025.

The battery-powered machines enable Lou’s colleagues to work cleaner, greener, and quieter. They’ve also helped trim maintenance costs. “When a gas-powered lawnmower hits a rock or stump, the blade keeps spinning, and that can damage the blade and engine parts,” he says. “When an electric mower blade hits something hard, the motor bypasses and stops the blade, which saves the part.”

Lou says he inherited his work ethic from his father, a carpenter who later worked in the concrete business. “He taught me how to work hard and work right.”

Photo by Robert DeSanto

Photo by Robert DeSanto

Apple Computer

David Highsmith, manager

Network Operations, Information Technology

When David Highsmith’s work goes unnoticed by the Yale community, that’s a good thing: It means everything is running smoothly. He and his team of network operations specialists manage the university’s wired and wireless networks, supporting a complex campus infrastructure system vital for work, teaching, and research.

“We know that the thousands of people on campus might not be thinking about how they’re connected,” David says. “They only care that they are connected, and we work to ensure they stay that way.”

As part of the department’s ongoing network development, David also supports the implementation of the multi-year Next Generation Network project, which will provide Yale with a more modern, resilient, and secure information network. “IT is a very, very interesting field because it is forever changing and evolving,” David says. “I’m always wondering where it’s headed next.”

What’s your tool of the trade?

“Tools of the Trade” will be an ongoing series. We want to hear from you: What is YOUR tool of the trade? Email the editor at youryalenews@yale.edu.